Service

- Our goal is to provide our global clientele with the best possible spinning performance and optimum product value. In order to provide you an unmatched buying experience, we provide a variety of effective pre- and after-sale services.

- After all, nothing should be left up to chance while managing sliver.

Pre - Sale

Recognize Your Needs

Making the appropriate sliver can selections and deploying them as effectively as feasible is essential to maximizing plant output and optimizing operating efficiency.

In the end, you must inform us of your desires for a sliver can:

- Height and width of sliver can.

- Thickness of HDPE sheet of sliver can.

- The color of sliver can.

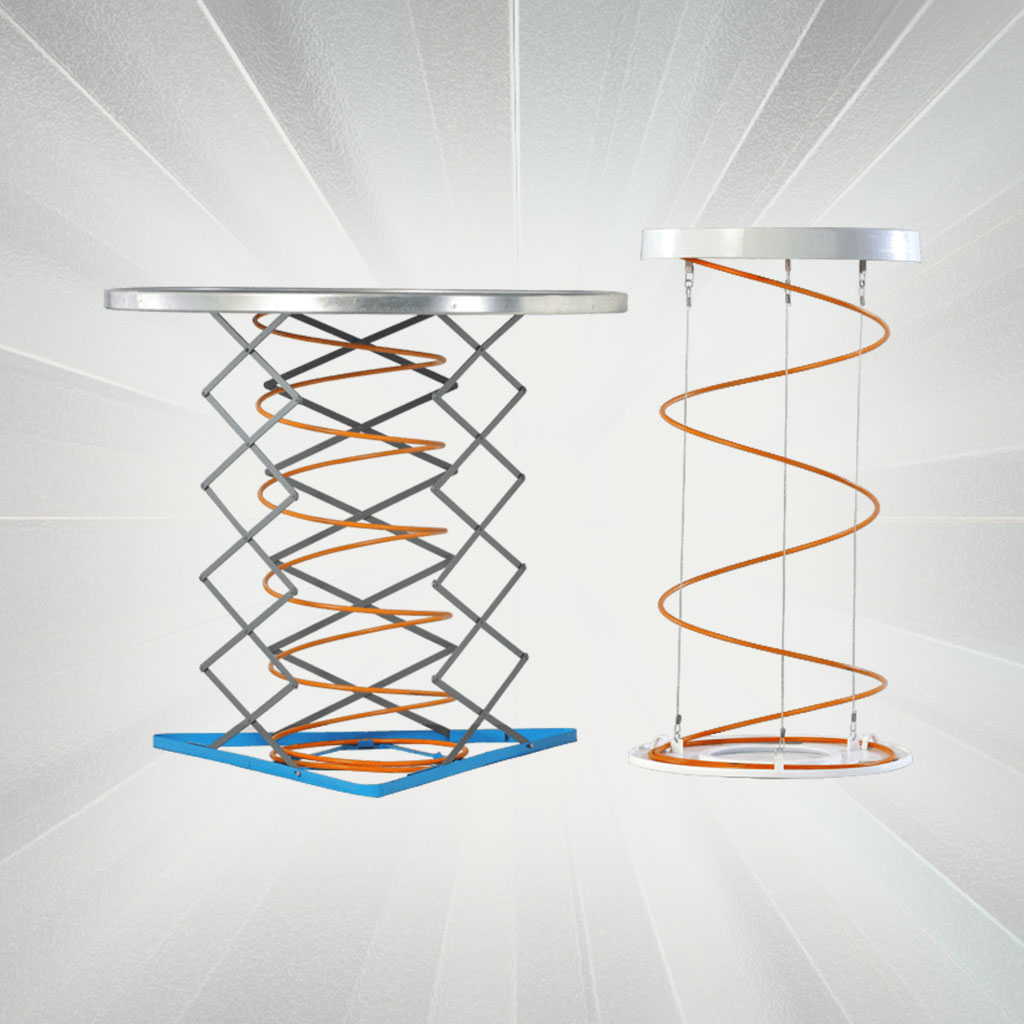

Spring Load Recommendations

Sliver cans must have the proper spring load to maintain total stability and reduce the possibility of tilting, which will increase their useful life and lifespan. Properly loaded cans minimize fatigue, maximize sliver handling throughout the spinning process, and enhance yarn quality.

Ordering Requirements for Spring Information:

- Procedure (drawing, carding, etc.)

- Type of lid (metal or plastic), weight, and location of the lid with relation to can top.

- Spring pretension if necessary.

- Can dimensions: diameter and interior height.

- Kind of fiber (e.g., polyester, cotton).

- Weight of stock (fiber) at full can.

After-sale

Can Assembling

Here are step-by-step instructions to assist you in building and utilizing our sliver cans, from disassembling the various parts (body plate, springs, top and bottom fittings, casters, etc.) to assembling the finished can.