Sliver cans are indispensable in spinning plants, serving as critical containers for slivers between various stages of yarn production. Proper maintenance and care of sliver cans are essential to ensure the efficiency, quality, and longevity of the spinning process.

This article outlines routine maintenance practices, common issues and troubleshooting tips, and long-term care strategies to extend the life of sliver cans.

Routine Maintenance Practices

Routine maintenance of sliver cans ensures they remain in optimal working condition, reducing downtime and maintaining product quality. Here are essential practices:

Regular Cleaning: Frequent cleaning of both the interior and exterior of sliver cans is crucial. Dust, lint, and other debris can accumulate and cause contamination or damage. Use soft brushes or compressed air to remove debris and ensure the cans are free from foreign materials that could affect the sliver.

Inspection for Damage: Make routine checks to look for any indications of damage, such as dents, cracks, or jagged edges. These flaws may lower the sliver’s quality and result in problems with operation. Cans that are damaged should be replaced or repaired right away.

Lubrication: Proper lubrication of the wheels and axles is essential for smooth movement. Employ the lubricants that the manufacturer recommends; do not overlubricate as this might draw in additional dust and debris.

Alignment and Balancing: Ensure that sliver cans are correctly aligned and balanced. Misalignment can cause uneven sliver distribution and lead to yarn quality problems. Regularly check and correct the alignment to ensure uniform weight distribution.

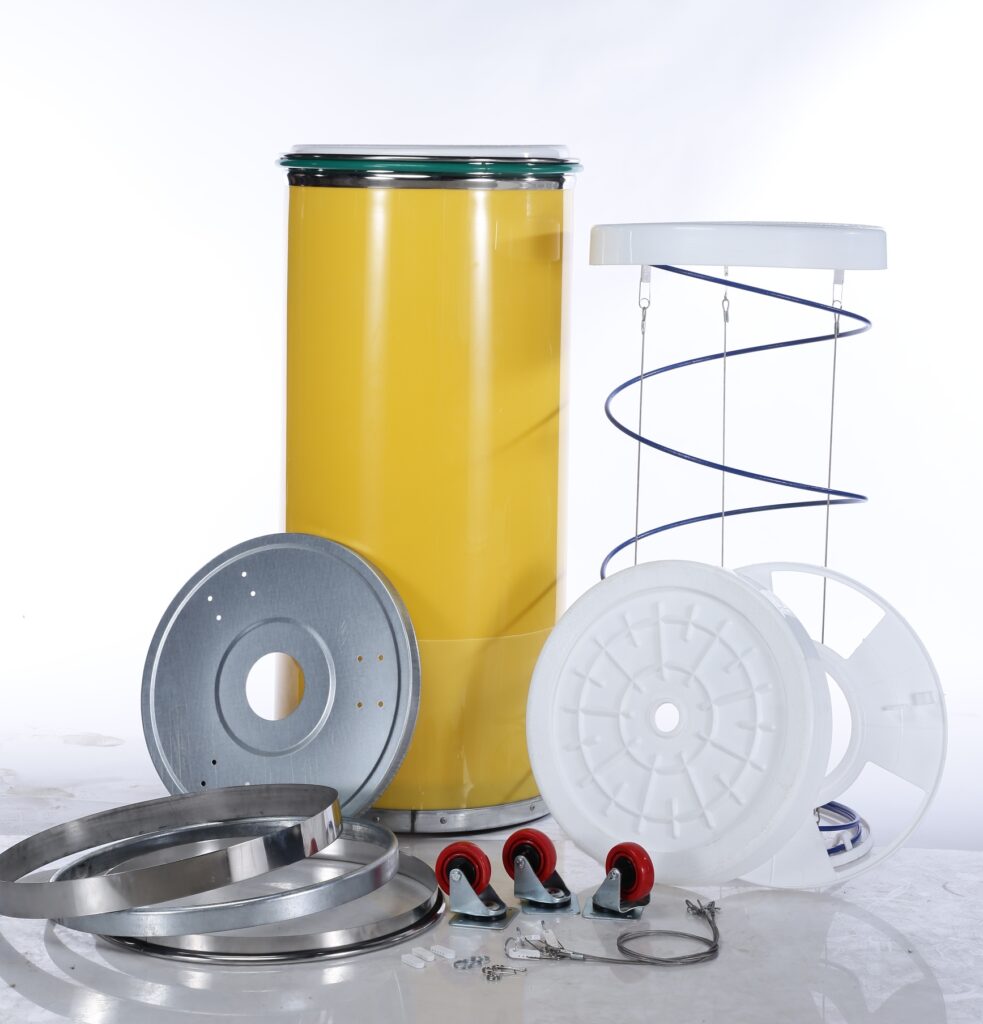

Replacement of Worn Parts: Over time, parts such as wheels, axles, and bottom plates may wear out. Check these parts often, and replace them with suitable, high-quality parts from reliable providers as necessary.

Common Issues and Troubleshooting Tips

Despite regular maintenance, sliver cans can encounter several issues. Here are some common problems and their solutions:

Sliver Breakage: This issue can result from sharp edges or rough surfaces inside the can. Inspect the interior for any roughness and smoothen it using appropriate tools. Additionally, ensure the cans are clean and free from contaminants.

Uneven Sliver Distribution: Uneven distribution can arise from misaligned cans or uneven surfaces. Check the alignment regularly and ensure the cans are level on the floor. Inspect and replace bottom plates if they are warped or damaged.

Difficulty in Movement: If sliver cans are difficult to move, check the wheels and axles for proper lubrication and wear. Clean the wheel axles regularly to prevent lint and dust buildup. Replace worn-out components to ensure smooth operation.

Noise During Operation: Unusual noises can indicate mechanical issues such as loose parts or damaged wheels. Replace any damaged wheels right away and tighten any loose screws or nuts. Avoid overloading cans, as this can strain the wheels and axles.

Long-term Care Strategies

Implementing long-term care strategies can significantly extend the life of sliver cans and ensure their continued efficiency:

Scheduled Overhaul: Beyond routine maintenance, schedule periodic overhauls for a comprehensive inspection and servicing of the cans. This includes replacing worn-out parts, thorough cleaning, and re-lubrication of all moving components.

Good Storage: To avoid rust and corrosion, keep silver cans in a dry, clean environment. Avoid stacking them in a way that could cause deformation or damage. The integrity of the cans is preserved in part by appropriate storage conditions.

Employee Education: Train employees on proper handling and maintenance of silver cans. Teach them about proper cleaning techniques, inspection techniques, and the significance of reporting problems as soon as they arise.

Use of Premium Cans: Make an investment in premium, long-lasting silver cans. Although the initial cost may be higher, these cans offer better performance and longer lifespan, reducing the frequency of replacements.

Monitoring and Documentation: Keep thorough records of all maintenance procedures, fixes, and replacements. Monitoring the performance and condition of the cans can help identify wear patterns and address issues proactively.

Preventive Maintenance Schedule: Create and follow a schedule of preventive maintenance that is relevant to your spinning plant’s requirements. This plan should outline regular maintenance tasks, inspection schedules, and criteria for part replacements.

Conclusion

The maintenance and care of sliver cans in spinning plants are crucial for ensuring smooth operations and high-quality yarn production. By following routine maintenance practices, addressing common issues promptly, and implementing long-term care strategies, spinning plants can significantly enhance the lifespan and efficiency of their sliver cans.

Investing time and resources in proper care pays off through consistent performance, reduced downtime, and lower operational costs. Regular attention to these critical components ensures that the spinning process remains efficient and the final product meets the highest quality standards.