Sliver cans are crucial in the textile industry for storing and transferring sliver during spinning. The material composition affects performance and durability. This article compares HDPE, metal, and composite sliver cans, highlighting their properties, applications, and performance.

Productivity and efficiency are increased by industry specialists who are aware of the benefits and drawbacks of each material.

High-Density Polyethylene (HDPE) Sliver Cans

Material Properties

High-Density Polyethylene (HDPE) is a thermoplastic polymer known for its strength-to-density ratio. HDPE sliver cans provide a number of benefits, such as being lightweight, resilient to moisture and chemicals, and long-lasting. Because of these characteristics, HDPE silver cans are extremely durable and appropriate for a range of industrial settings. However, HDPE sliver cans may lack the structural strength of metal sliver cans, which can be a consideration in specific high-stress applications.

Manufacturing Process

The manufacturing of HDPE sliver cans involves extrusion and molding processes. HDPE pellets are melted and extruded into desired shapes, followed by cooling and molding to form the final product. Recent innovations in HDPE manufacturing include improvements in molding techniques and material formulations, enhancing the strength and durability of the sliver cans.

Pros | Cons |

|

|

Applications in Textile Industry

The textile industry makes extensive use of HDPE sliver cans for the storage and transportation of sliver. Staff workers don’t have to exert as much physical effort handling and moving them because of their modest weight. HDPE sliver cans are particularly beneficial in environments where chemical exposure and moisture are prevalent, as they resist corrosion and degradation.

Performance and Longevity

HDPE sliver cans have a considerable lifespan, often outlasting other materials under specific conditions. They require minimal maintenance, with simple cleaning procedures to ensure longevity. Case studies from industry usage show that HDPE sliver cans perform well in various textile processes, providing a reliable and cost-effective solution.

Environmental Impact

HDPE is recyclable, making HDPE sliver cans an environmentally friendly option. The recycling process involves melting down used HDPE products and reforming them into new items, reducing waste and environmental impact. Because they are lightweight and recyclable, HDPE sliver cans have a lower carbon impact than other materials.

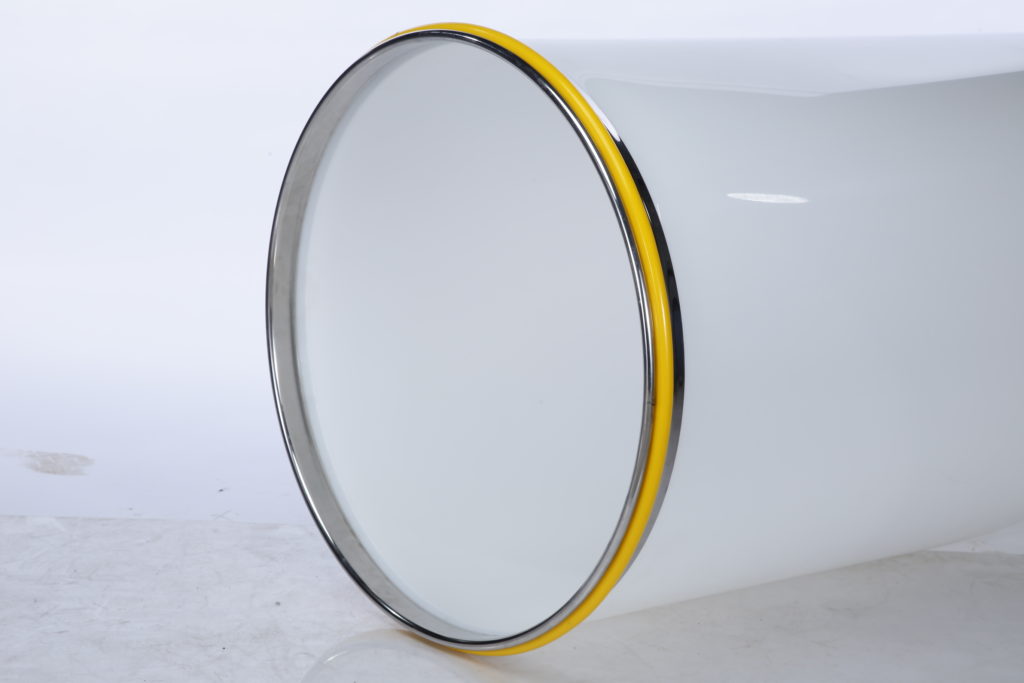

Metal Sliver Cans

Material Properties

The most common materials used to make metal sliver cans are aluminum or stainless steel, which provide exceptional rigidity and strength. Because of these characteristics, metal sliver cans are incredibly strong and resistant to physical harm. They are appropriate for high-temperature settings since they are also heat-resistant. However, the heavier weight of metal sliver cans can be a disadvantage, making them more challenging to handle and transport.

Manufacturing Process

The manufacturing process for metal sliver cans involves cutting, forming, and welding metal sheets into the desired shapes. Technological advancements in metal fabrication, such as precision laser cutting and automated welding, have improved the quality and efficiency of production. These advancements ensure consistent performance and durability of metal sliver cans.

Pros | Cons |

|

|

Applications in Textile Industry

For situations where stiffness and strength are essential, metal sliver cans are the ideal choice. They are frequently employed in procedures requiring large weights and high-stress situations. They are appropriate for some heat-treated textile production stages because of their tolerance to high temperatures.

Performance and Longevity

Metal sliver cans have an extended lifespan, often lasting for many years with proper maintenance. Routine maintenance includes periodic wear and tear repairs as well as rust prevention. Case studies demonstrate how well metal sliver cans function in harsh settings, offering dependable performance in difficult circumstances.

Environmental Impact

Because metal sliver cans are recyclable, the textile industry’s environmental initiatives benefit from them. Metal recycling entails melting down waste metal and repurposing it into new goods. However, the environmental effect of metal sliver cans can be larger due to the energy-intensive nature of metal manufacture and recycling procedures.

Composite Sliver Cans

Material Properties

In order to attain particular performance qualities, composite sliver cans are constructed from a mix of materials, such as fiberglass and resin.These materials provide specific qualities for a range of applications while offering a balance between strength and weight. Composite sliver cans are designed to offer the benefits of both HDPE and metal sliver cans, with fewer disadvantages.

Manufacturing Process

The manufacturing process for composite sliver cans involves layering materials and curing them to form a solid structure. The performance of silver cans has been improved by advancements in composite material technology, which have produced stronger and more resilient composite materials. Techniques such as vacuum infusion and autoclave curing are used to ensure high-quality composite products.

Pros | Cons |

|

|

Applications in Textile Industry

Composite sliver cans are used in niche or specialized textile processes where specific performance characteristics are required. They are appropriate for a variety of uses, from typical storage and transit to high-stress situations, thanks to their specific qualities. The versatility of composite sliver cans allows them to meet diverse needs in the textile industry.

Performance and Longevity

Composite sliver cans have a long lifespan, with durability comparable to metal sliver cans but with the added benefit of reduced weight. Maintenance requirements are minimal, and composites are resistant to many forms of physical and chemical damage. Industry usage examples demonstrate the reliability and effectiveness of composite sliver cans in various applications.

Environmental Impact

The environmental impact of composite sliver cans varies depending on the materials used. Some composites are recyclable, while others may be more challenging to recycle. However, advancements in composite recycling technologies are improving the sustainability of these materials. The overall environmental benefits of composite sliver cans include reduced weight and increased durability, leading to lower transportation and maintenance costs.

Comparative Analysis

Weight and Maneuverability

HDPE sliver cans are the lightest, offering excellent maneuverability and ease of transport. Metal sliver cans are heavier, which can be a disadvantage in terms of handling but an advantage in terms of stability. Composite sliver cans provide a balance, offering sufficient strength while being lighter than metal.

Durability and Resistance

Metal sliver cans are the most durable in high-stress environments, offering excellent resistance to physical damage and heat. HDPE sliver cans are highly resistant to chemicals and moisture, making them suitable for environments with exposure to such elements. Composite sliver cans offer a combination of durability and resistance, tailored to specific applications.

Cost and Economic Considerations

Sliver cans made of HDPE are usually the least expensive since they require less upkeep and have lower startup costs. Metal sliver cans may be more expensive to maintain over time and at first. Composite sliver cans tend to be the most costly, reflecting their tailored properties and advanced manufacturing processes. However, the long-term economic impact may favor composites due to their durability and versatility.

Performance in Textile Processes

HDPE sliver cans perform well in standard textile processes, offering reliability and ease of use. Metal sliver cans excel in demanding and high-temperature environments, providing the necessary strength and stability. Composite sliver cans are versatile, performing well in a wide range of applications and offering tailored properties to meet specific needs.

Safety Considerations

Safety features of sliver cans vary by material. HDPE sliver cans are safe to handle, with no sharp edges and resistance to chemicals. Metal sliver cans require precautions to prevent rust and handle their weight safely. Composite sliver cans offer safety benefits similar to HDPE, with additional strength and durability. Industry regulations and compliance ensure that all types of sliver cans meet safety standards.

Conclusion

HDPE, metal, and composite sliver cans each have pros and cons. HDPE cans are lightweight, cost-effective, and resistant to chemicals and moisture. Cans made of metal are stronger, more resilient to heat, and more durable. Composite cans balance properties with reduced weight and high durability.

When selecting a sliver can, professionals should consider their textile process requirements, environmental conditions, and budget. Future trends in materials and technology will enhance the performance and sustainability of these essential components in the textile industry.