Sliver cans are crucial in textile manufacturing for transporting and storing sliver, a loose, untwisted strand of fibers, before spinning into yarn. Their quality affects both the sliver and the final textile products.

This article examines the key components of sliver cans, focusing on their materials, construction, and roles in effective sliver handling.

Body Sheet

Material and Construction

Stainless steel or aluminum are common sturdy materials used to make the body sheet of a sliver can. Stainless steel is favored for its strength, corrosion resistance, and long lifespan, while aluminum is appreciated for its lightweight properties. The body sheet is usually formed through a process of rolling and welding, ensuring a seamless and sturdy construction.

Durability and Strength

The durability of the body sheet is crucial, as sliver cans are subject to frequent handling, transportation, and storage. A strong body sheet prevents dents and deformations that could compromise the integrity of the sliver inside. The rigidity of the body sheet also ensures that the can maintains its shape, providing a consistent environment for the sliver.

Upkeep and Concern

Maintaining the body sheet requires regular upkeep in order to increase its lifespan. This include dusting and contaminating as little as possible, checking for wear and damage, and fixing anything that needs fixing. Sufficient maintenance guarantees that the body sheet stays in top shape, protecting the sliver’s quality.

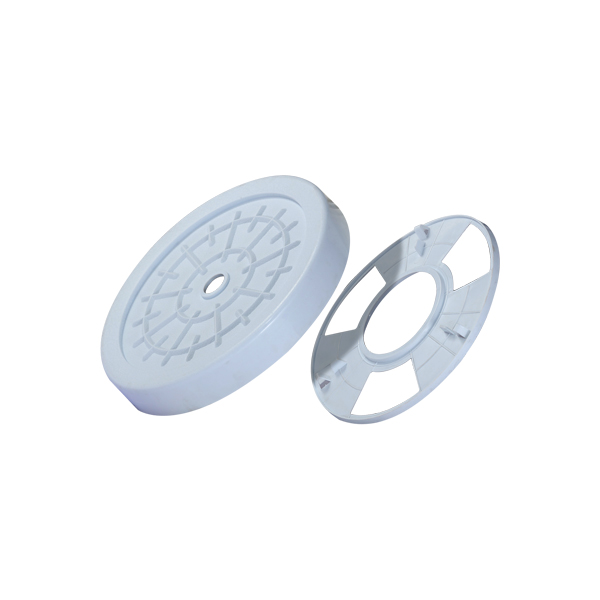

Castors and Dust Wheel

Types of Castors

Castors, or wheels, are essential for the mobility of sliver cans. They come in various types, including fixed castors, which provide stability, and swivel castors, which allow for greater maneuverability. Some cans also feature locking castors to keep the can stationary when needed.

Material and Design

Castors are commonly made from durable materials such as polyurethane, which offers a balance of strength, flexibility, and resistance to wear. The design of castors is critical in reducing noise and ensuring smooth movement across different surfaces. Dust wheels, often attached to the castors, help minimize the accumulation of dust and debris, which can affect both the castors’ performance and the sliver quality.

Benefits for Sliver Handling

High-quality castors and dust wheels facilitate the easy movement of sliver cans, reducing the risk of spills and damage to the sliver. Their smooth operation ensures that sliver cans can be transported efficiently within the production facility, maintaining the continuity and quality of the sliver.

Spring With Pantograph

Function and Mechanism

The spring with pantograph mechanism is a vital component that helps maintain consistent tension on the sliver. This mechanism allows for the smooth and even feeding of sliver during the spinning process, ensuring uniformity in the final yarn.

Material and Construction

Springs are typically made from high-strength steel, capable of withstanding repeated stress without losing their elasticity. The pantograph, a system of pivoting arms, is designed to adjust dynamically, accommodating variations in sliver length and thickness.

Importance for Sliver Control

Maintaining even tension is crucial for preventing breakage and ensuring the uniformity of the sliver. The spring with pantograph mechanism ensures that sliver is fed at a consistent rate, reducing the occurrence of weak spots and variations in the final yarn.

Top and Bottom Cover

Material and Design

The top and bottom covers of sliver cans are usually made from robust materials such as stainless steel or high-grade plastic. These covers are designed to fit securely, protecting the sliver from external contaminants while allowing for easy access when needed.

Protection and Containment

The primary role of the top and bottom covers is to protect the sliver from dust, moisture, and other contaminants that can affect its quality. They also provide containment during transportation and storage, preventing the sliver from spilling out and getting damaged.

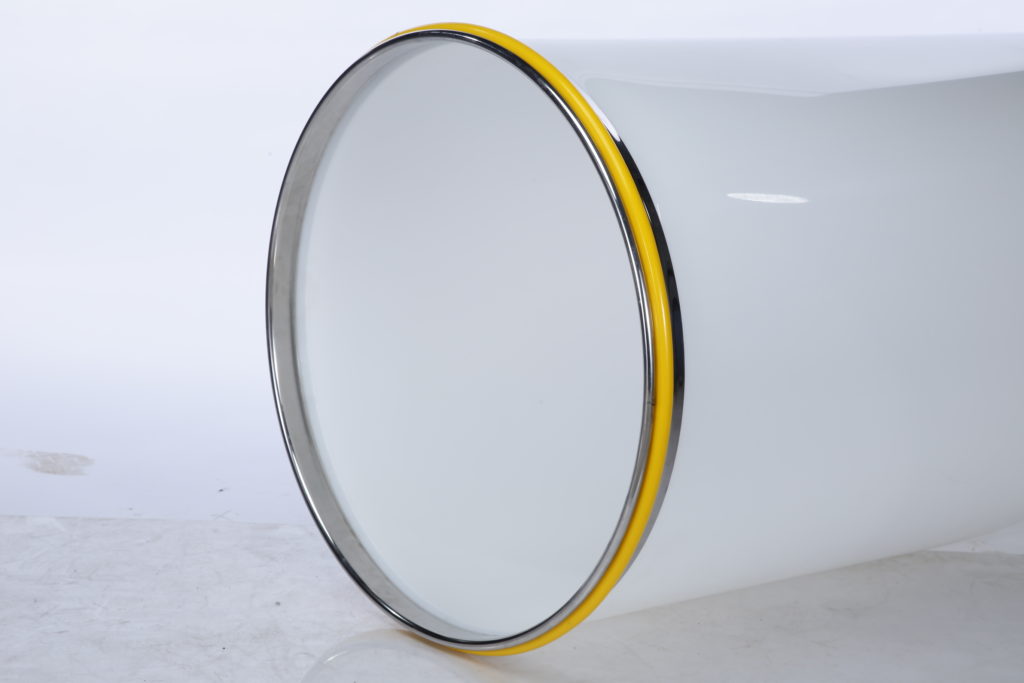

Upper Ring and Anti-shock Ring

Function and Importance

The sliver can’s durability and structural integrity are improved by the anti-shock ring and top ring. The upper ring reinforces the top of the can, while the anti-shock ring absorbs impacts, reducing the risk of damage during handling.

Material and Construction

These components are typically made from resilient materials such as rubber or reinforced plastic, capable of withstanding significant stress and impacts. The construction involves molding or extruding these materials into the required shapes, ensuring a precise fit.

Benefits for Durability

The addition of the upper ring and anti-shock ring significantly enhances the lifespan of sliver cans. They help maintain the shape of the can, prevent dents and deformations, and protect the sliver from external shocks, ensuring consistent quality.

Handle

Design and Ergonomics

The handle of a sliver can is designed for ease of use, typically featuring an ergonomic shape that allows for a comfortable grip. This design consideration is crucial for reducing strain on workers and facilitating the smooth handling of sliver cans.

Material and Construction

Handles are usually made from sturdy materials such as metal or high-strength plastic, ensuring they can withstand the weight and frequent use. The construction involves securely attaching the handle to the can body, often with reinforced brackets or screws.

Importance for Mobility

Handles play a vital role in the mobility of sliver cans, allowing workers to easily lift, carry, and maneuver the cans as needed. This enhances efficiency in the production process and helps maintain the integrity of the sliver by reducing the risk of drops and mishandling.

Integration of Components

Synergy Between Components

Each component of a sliver can plays a crucial role, and their integration ensures the overall functionality and efficiency of the can. The body sheet provides structural support, castors enable mobility, springs with pantographs maintain tension, and covers protect the sliver. Together, these components work in synergy to create a reliable and effective solution for sliver handling.

Impact on Sliver Quality

The quality of sliver is directly impacted by the quality and design of the sliver can components. Proper integration ensures that the sliver remains undamaged, uncontaminated, and consistently fed into the spinning process, resulting in high-quality yarn with uniform properties.

Conclusion

Sliver cans are vital in the textile industry, with components like the body sheet, castors, dust wheels, springs, covers, rings, and handles crucial for maintaining sliver quality. High-quality materials, precise construction, and proper maintenance are essential.

Investing in high-quality sliver cans and proper handling boosts yarn quality and production efficiency. Innovations in design and materials, including ergonomic and smart technologies, will further enhance their effectiveness.